In an environment of labor shortages, material delays, and heightened contractual requirements, how do you complete a project months ahead of schedule while maintaining safety and quality?

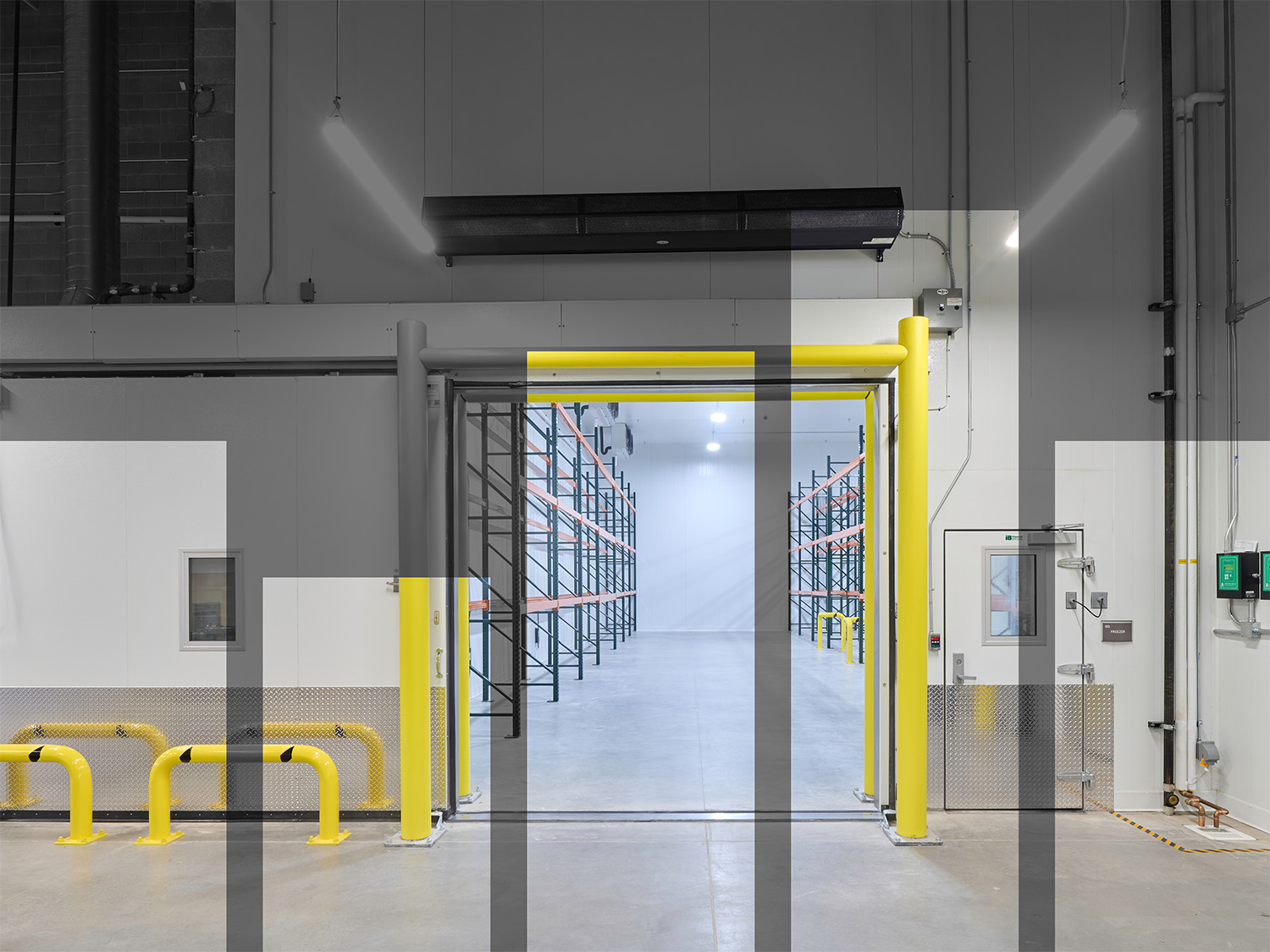

HB recently celebrated completion of the Las Cruces Public Schools Tashiro Food Service Warehouse, a tilt-up concrete structure with a large refrigerator and freezer. The warehouse was the initial phase of the planned LCPS Tashiro campus, which will provide logistical support, storage, and maintenance for LCPS operations. HB and its partners finished six weeks ahead of schedule using a combination of time-tested and innovative approaches.

Time-tested: Proactive Schedule Management

Our team coordinated with trusted local partners prior to bid date to clarify schedule expectations and project requirements. In addition to vetting critical lead times, HB spent time analyzing constructability of the building’s pitched metal roof and supporting members. Other measures included:

- Weekly updates to the schedule based on work in place, foreman meeting coordination, and material delivery timelines.

- Intensive submittal and shop drawing coordination to fully confirm walk-in refrigerator/ freezer construction methods, including connections to the foundation, mechanical piping, and equipment.

- Formal quality plan to ensure all installations, including extensive site work around the campus, were done correctly the first time.

Innovative: Schedule Health Checks

In addition to proven best practices, the HB team used schedule analytics to objectively score schedule quality and health. Traditionally, schedules are built and managed using software that provides no feedback on actual viability, meaning contractors can inject their best hopes for timeliness by compressing or improperly overlapping tasks. Using a customized deployment of schedule analytics software, HB took advantage of data within the schedule to realistically measure and improve performance. Generally, this entails applying formulas across all durations and relationships of current and previous schedules, aided by software. This approach yielded key advantages at Tashiro:

- Baseline schedule quality grading to help refine shorter durations and actionable logic for subcontractor crews.

- Critical path health continual analysis and visible score.

- Overall project health index.

- Realistic forecasting using past project performance as a predictive tool.

- HB made scoring and reports presented to Owner and Architect team to increase visibility and provide an objective baseline for coordination.

The success of the Tashiro Food Service Warehouse project was a direct result of collaborative effort, attention to detail, and commitment to overcoming challenges. By integrating technology with solid management, the team not only met the project’s demands but also defied industry trends, delivering better results for Las Cruces Public Schools.